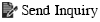

100 MM HEAVY Cap

100 MM HEAVY Cap Specification

- Packaging Type

- Box

- Features

- Leak proof, Airtight, Durable, Corrosion Resistant

- Cap Type

- Twist-Off

- Shape

- Round

- Product Type

- Cap

- Material

- Tinplate / Metal

- Type

- Heavy Cap

- Treatment

- Rust Resistant Coated

- Usage

- Jar Sealing, Bottle Capping

- Lacquer

- Food Grade Epoxy

- Diameter

- 100 mm

- Width

- 100 mm

- Size

- 100 mm

- Color

- Silver

- Application

- Food, Beverage, Pharmaceutical

- Thread Type

- Continuous Thread

- Standards

- FDA Approved Material

- Finish

- Glossy

- Temperature Resistance

- Up to 120°C

- Custom Printing

- Available

- Inner Lining

- PVC / BPA Free

- MOQ

- 1000 pieces per order

- Weight

- Approx. 20 grams

100 MM HEAVY Cap Trade Information

- Minimum Order Quantity

- 10000 Pieces

- Supply Ability

- 30000 Pieces Per Week

- Delivery Time

- 8 TO 10 Days

About 100 MM HEAVY Cap

Technical Specification

| Minimum Order Quantity | 10000 Piece |

| Weight | 12 gm,15 gm |

| Size | 100mm |

| Weight (g) | 12gm & 15gm |

| Neck Size (mm) | 100mm & 120mm |

| Material | PP |

| Color | As per required |

Premium Quality for Sensitive Applications

Engineered with FDA-approved materials and a PVC/BPA-free inner lining, this cap upholds the highest standards required for food, beverage, and pharmaceutical products. Its food-grade epoxy lacquer ensures contents remain uncontaminated, while the rust-resistant coating protects against environmental damage, making it suitable for both local and export markets.

Customizable and Versatile Design

With a 100 mm diameter and an approximate weight of 20 grams, the cap fits a wide variety of jars and bottles. Custom printing options enable branding flexibility, while its continuous thread and twist-off type ensure user-friendly sealing and opening. Its leak-proof and airtight construction maintains product freshness and safety.

Strong and Reliable Packaging Solution

Packaged securely in boxes, each cap is designed to provide an airtight seal under fluctuating temperatures, up to 120C. Its metal construction ensures long-term durability, while the corrosion-resistant treatment further extends its service life, making it an excellent choice for businesses looking for reliable capping solutions.

FAQs of 100 MM HEAVY Cap:

Q: How does the 100 MM HEAVY Cap ensure airtight and leak-proof sealing?

A: The cap is engineered with a continuous thread and twist-off mechanism, combined with a PVC/BPA-free inner lining and food-grade epoxy lacquer. This construction creates a reliable, airtight, and leak-proof seal, keeping contents fresh and secure.Q: What materials are used in the cap, and are they safe for food and pharmaceuticals?

A: Constructed from high-quality tinplate/metal, the cap is coated with a rust-resistant layer and lined with FDA-approved, PVC/BPA-free material. The food-grade epoxy lacquer further enhances safety, making it ideal for sealing items in the food, beverage, and pharmaceutical sectors.Q: When should I consider using this heavy cap in my packaging process?

A: This cap is recommended when you need secure sealing for jars and bottles exposed to varying temperatures (up to 120C), and for products where safety, durability, and adherence to standards are critical, typically in food, beverage, or pharmaceutical packaging.Q: Where can the 100 MM HEAVY Cap be applied in terms of industry and usage?

A: The caps are versatile and applicable in various industries, including food processing, beverage bottling, and pharmaceutical packaging. They are suitable for use in both small-scale and large-scale packaging operations.Q: What is the process for ordering and customizing these caps?

A: Customers can place orders starting from a minimum of 1000 pieces. Custom printing is available to accommodate brand requirements. Simply provide your specifications, and the manufacturer will handle the customization and supply.Q: How do the caps features benefit exporters, suppliers, and manufacturers?

A: The caps rust-resistance, durable build, and compliance with FDA standards enhance product integrity during transport and storage. Its airtight, leak-proof qualities reduce spoilage risks, supporting exporters, suppliers, and manufacturers in maintaining quality across distributions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plastic Caps Category

Plain Fridge Bottle Cap 46mm

Price 1.30 INR / Piece

Minimum Order Quantity : 10000 Pieces

Product Type : Fridge Water Bottle Cap

Material : Plastic

Color : Customized

Diameter : 46 Millimeter (mm)

Plastic Ring Fridge Bottle Cap

Price 2.40 INR / Piece

Minimum Order Quantity : 10000 Pieces

Product Type : Fridge Water Bottle Cap

Material : Plastic

Color : Pink, Green, Blue etc

Diameter : 46 Millimeter (mm)

Flip Top Cap 24mm

Price 1.40 INR / Piece

Minimum Order Quantity : 10000 Pieces

Product Type : Plastic Flip Cap

Material : Plastic

Color : Green, Transparent, Blue, Black and White

Diameter : 24 Millimeter (mm)

Lotion Dispenser Pump 24mm

Price 5.70 INR / Piece

Minimum Order Quantity : 5000 Pieces

Product Type : Lotion, Dispenser and Oil Use

Material : Plastic

Color : Black, White and Gold

Diameter : 24 Millimeter (mm)

|

MAHESHWARI POLYMERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free